Maserati Manual MK1

Mistral + 3500 GT Owner's Manual

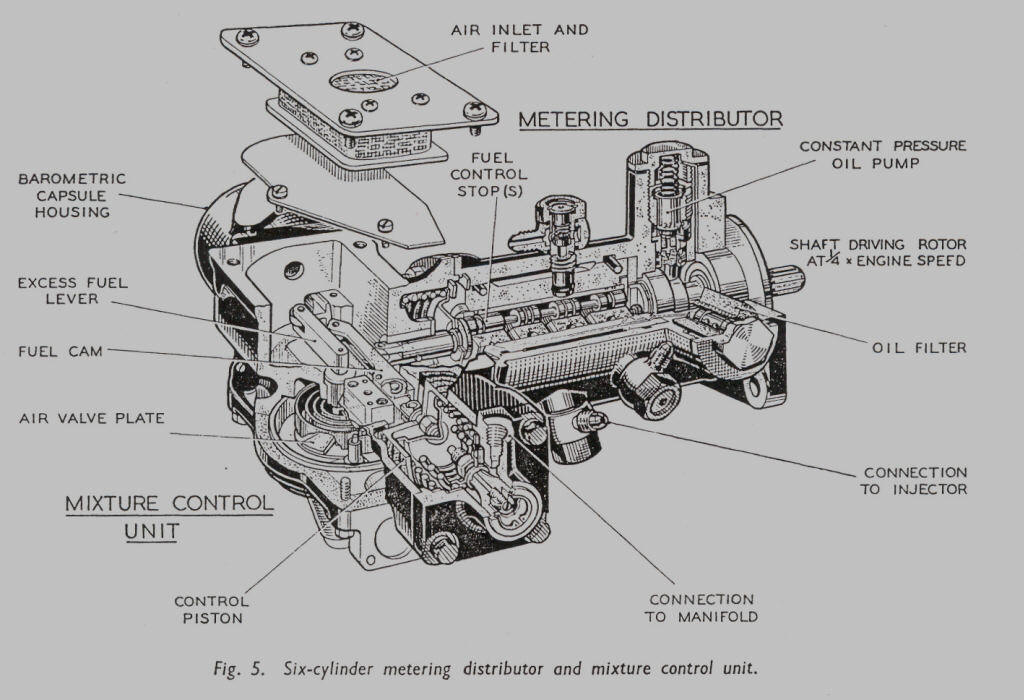

Construction of Six-Cylinder Metering Distributor

Fig. 5 shows the constructional features of a six-cylinder metering distributor

and mixture control unit. The former

consists of two three-cylinder units combined in one rotor which is driven at

one-quarter engine speed, the inlet and

outlet ports being arranged so that each cylinder receives one injection of fuel

per intake stroke. The shuttles in the

two bores are phased to begin injection at intervals of 120 engine degrees. The

control stops, by means of which the

fuel quantity is adjustable, abut against a face in the mixture control unit,

described below.

A constant pressure pump, operated by a small eccentric cam on the drive shaft,

pumps engine oil at about 105 p.s.i.

which is used for preventing leakage of fuel from the rotor ends and for

lubricating the control stop faces. From the

pump, oil is filtered and fed to a longitudinal drilling in the sleeve, from

which cross drillings lead to two oil grooves,

one at each end of the rotor. At the control stop end, drillings in the rotor

groove lead to the stops, feeding oil through

centres of the stops to the rubbing faces.

The hardened steel sleeve, complete with rotor and shuttle assembly, is floated

in rubber sealing rings in the

aluminum body casting, while between the driving shaft and the rotor driving

plate there is a self-aligning coupling

which allows for any slight misalignment of the rotor and sleeve assembly on its

rubber mounting.

The Mixture Control Unit

This unit is secured to the end flange of the metering distributor (Fig. 5) and

its purpose is to provide complete

control of the quantity of fuel according to load under normal running

conditions, with appropriate corrections for

changes in barometric pressure. In addition, it incorporates a manual control

for cold starting and warm-up conditions.

Fig. 5. "super

size" click here

Page 8

Click here to go to page 9