|

|

Lucas Service Training Centre

Petrol Injection Mk II

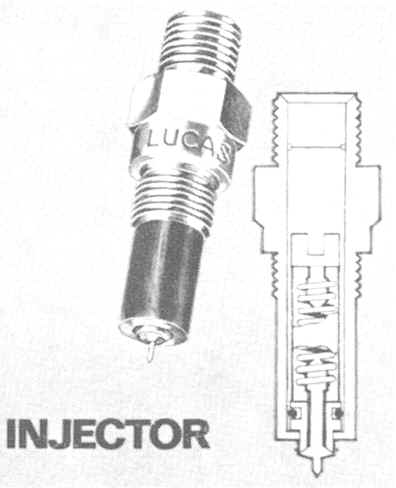

The fuel is injected into the engine cylinders by means of injectors of the forward opening poppet-valve type. Figure 11 shows the main features of the injector. Fuel enters the injector at the top. The nozzle valve is kept closed by spring pressure. The valve is designed to open at 50 lbf/in2 (344.73 kN/m2). The correct amount of fuel, in the form of a fine spray, is injected into the inlet manifold where it combines with the air, drawn in by the engine. The timing of the metering unit to the engine is set in accordance with the engine designers’ requirements. The injector is not adjustable in service. However, there is only one fault likely to occur. Impurities in the fuel may become trapped on the valve seat, and thus prevent the nozzle valve from closing. These impurities can usually be removed by connecting the injector to a filtered air-supply, having a pressure of about 80 lbf/in2 (551.50 kN/m2) in the forward direction. If, however, the injector remains ‘stuck open”, it should be renewed. |

|

|

FAULT DIAGNOSIS: PRELIMINARY CHECKS If the petrol injection system is suspected of not functioning correctly, the following preliminary checks should be carried out, as a failure in any of these would give the impression that the petrol injection system was faulty.

|

|

Page 12

Click here to go to page 13