Maserati Manual MK1

Mistral + 3500 GT Owner's Manual

THE METERING DISTRIBUTOR AND MIXTURE CONTROL UNIT

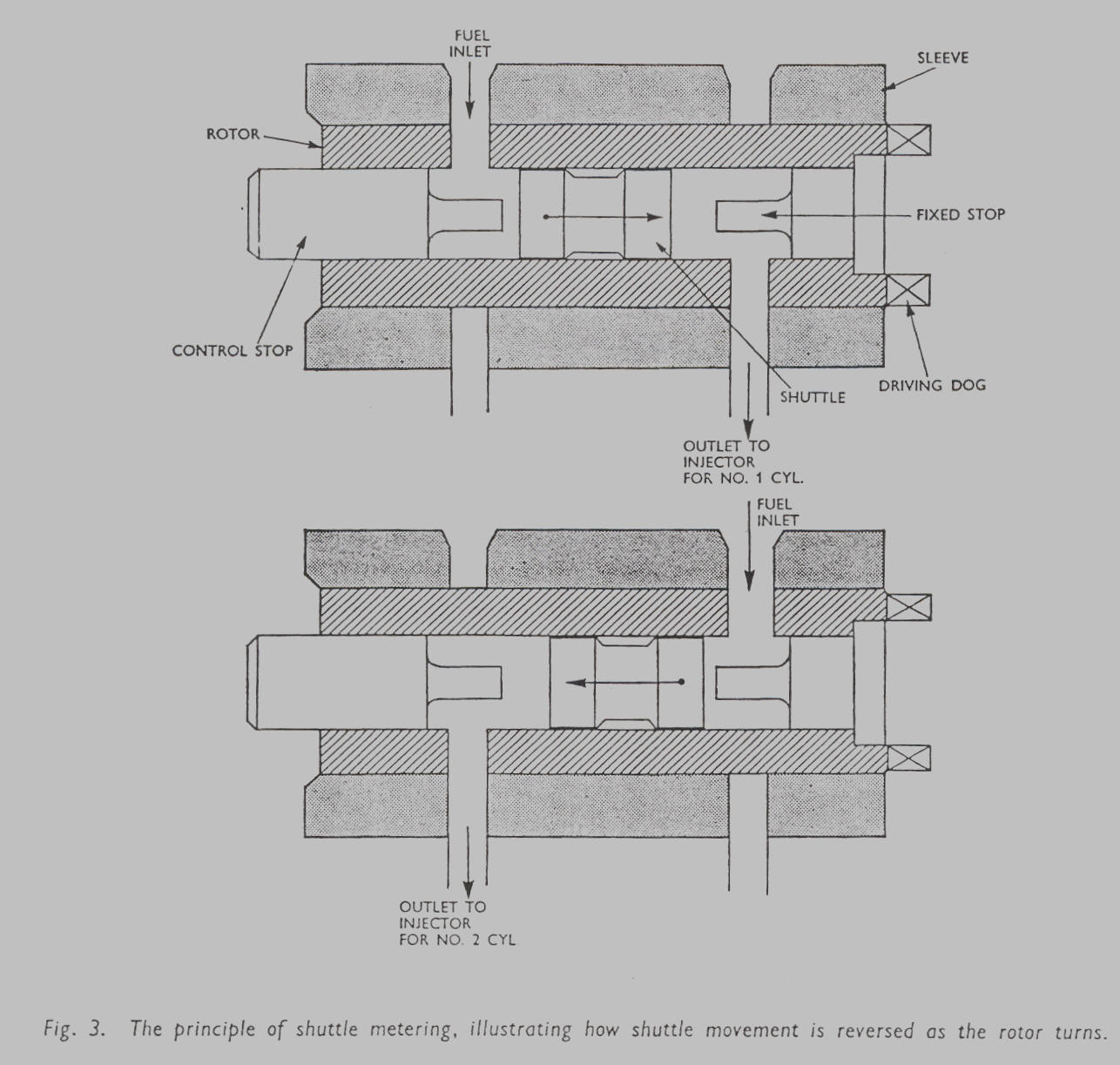

The Principle of Shuttle Metering

The principle of shuttle metering is illustrated in Fig. 3 which shows an

arrangement suitable for a two-cylinder

engine. An engine-driven rotor, having two radial ports leading to a bore in its

centre, fits in a sleeve containing fuel

inlet and outlet ports. The bore of the rotor contains a small shuttle capable

of moving axially between two stops. one

fixed and the other adjustable. As the rotor turns within the sleeve, the rotor

port at the control stop end becomes

coincident with the fuel inlet port in the sleeve (as shown in the upper

diagram). Fuel from the pump now enters at

pressure and drives the shuttle towards the fixed stop. displacing fuel which is

discharged through the rotor and sleeve

ports at that end to an injector. A further 180 degrees of rotation of the rotor will

result in the position shown in the lower

diagram, fuel now enters at the fixed stop end of the rotor. driving the shuttle

towards the control stop and displacing

an identical quantity of fuel to the second cylinder. In this way. the shuttle

moves to and fro between the two stops as

the rotor is driven round, and at each shuttle movement an accurately metered

amount of fuel is displaced and injected

into the appropriate cylinder. The quantity of fuel is the product of the area

of the bore and the distance of shuttle

travel. the latter being determined by the setting of the control stop.

Page 6

Click here to go to page 7

Click here to go to the table of contents