Maserati Manual MK1

Mistral + 3500 GT Owner's Manual

Petrol Injection Equipment

INTRODUCTION

On a petrol injection engine, the carburetor is replaced by a pressurized fuel

system which meters accurate charges

of fuel to each cylinder in turn. The fuel is injected in the form of a fine

spray into the intake air at a point in the

manifold close to the inlet valve. The mixture is then compressed and

spark-ignited in the usual manner.

The accurate control possible over the amount of fuel supplied to each cylinder

under all operating conditions

gives increased economy and greater flexibility to a petrol injection engine. In

addition the removal of the carburetor

choke, and the absence of the exhaust-heated hot spot, permit an increased air

charge to the engine, resulting in increased

power output.

As a result of many years of investigation into problems associated with petrol

injection, Lucas engineers have

developed a system which will serve four, six or eight cylinder engines

accurately and reliably. The ability of the system

to meet very high speed requirements is shown by its successful use on specially

designed racing engines with speeds

of the order of 10,000 r.p.m.

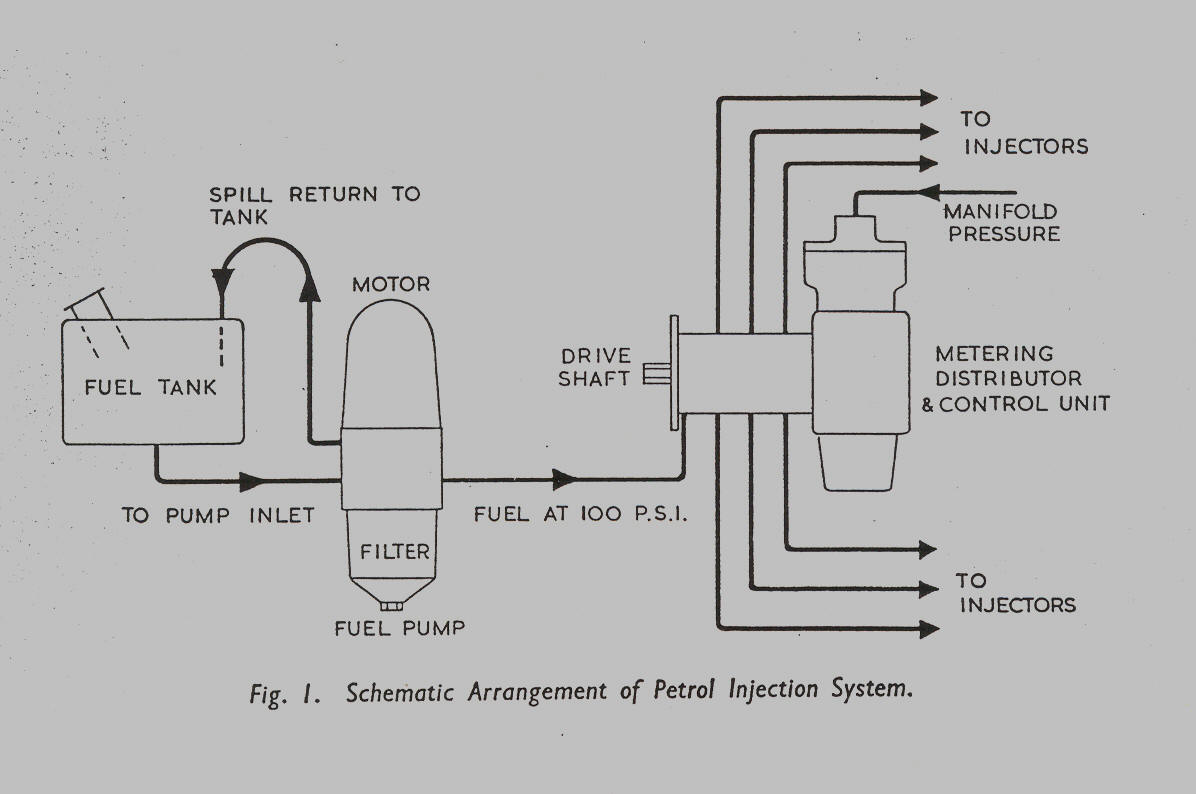

GENERAL DESCRIPTION OF THE SYSTEM

The system is illustrated schematically in Fig. 1. Briefly. a motor-driven

primary pump. mounted on the chassis

adjacent to the fuel tank, supplies fuel at a pressure of 100 p.s.i. to the

metering distributor mounted on, and driven by,

the engine. From the metering distributor, accurately timed and metered,

quantities of fuel are delivered at each

injector in turn; these are of poppet valve type, located in the manifold near

the intake ports, the fuel being discharged

into the intake air stream in the form of finely divided spray.

When the system is fitted to normal production high-performance engines, the

amount of fuel metered to the individual

injectors is determined automatically by the mixture control unit described on a

later page. This unit is mounted

integral with the metering distributor and takes its signal from a tapping on

the intake manifold. For racing engines,

which normally have a limited operating range at the upper end of the r.p.m.

scale, fuel control is achieved directly

by means of a profiled lever mounted on the metering unit and actuated by the

throttle linkage.

THE FUEL PUMP

The fuel pump (see Fig. 2) comprises a simple gear pump driven by a permanent

magnet motor operating at battery

voltage, and incorporates a paper filter element in the main fuel supply. A

relief valve returns excess fuel to the tank

and maintains the line pressure at 100 p.s.i.

Page 4

Click here to go to page 5