Maserati Manual MK1

Mistral + 3500 GT Owner's Manual

PROBLEMS IN THE MOTOR

Smoke is coming out of the exhaust pipes, the motor rumbles, it is not powerful

enough. The spark plugs look smoked and

the engine uses up too much gasoline.

(A) Check to see if the fuel pump is off, choke is off (the choke handle on the

dashboard should be turned completely to the left)

and that roller E (see figure 44) always keeps in contact with the point on the

barometric capsule.

(B) Check the motor idling, if the roller E in figure 44, detaches

automatically. In this case, check with a three way and a monometer

(figure 43) that the pressure is not over (102 TO 110 p.s.i) 7 to 7.5

atmospheres. A higher pressure would indicate that Valve A on the

fuel

pump (see figure 19) is jammed. Take it apart, clean it and, if necessary,

replace it.

(C) Check point B, in the chapter "DEFECTIVE IDLING".

(D) If A, B & C are correct, check the setting of one of the following systems.

(A) Replace the small roller (D) in figure 44, with a larger one, trying

progressively larger ones with a variation in the diameter of 0.05mm.

(B) Replace the small roller (E) in figure 44 with an under size roller, trying

progressively different rollers with diameter variations of 0.05mm.

(C) Progressively eliminate the extra thickness under the main spring A (See

figure 46) progressively.

(D) If there are no extra thicknesses, reduce progressively the thickness

of the spring by 0.02mm at a time. (See figure 46A) as an alternative, insert

under the cover R (See figure 45) cardboard rings (0), figure 45 with

progressively larger size from 0.2mm to a maximum of 1.5mm.

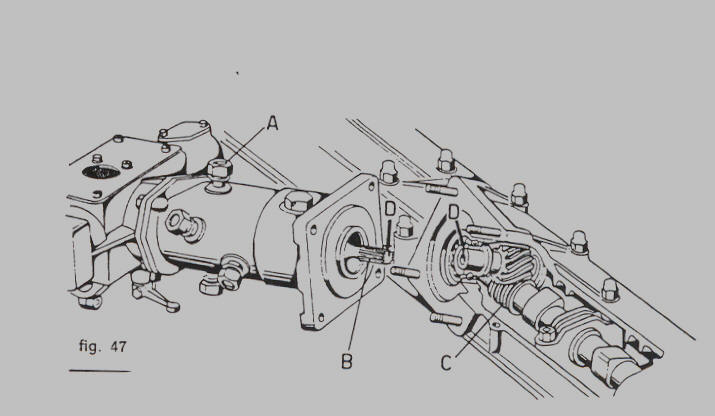

TIMING OF THE INJECTION DISTRIBUTOR

The starting point of the gasoline delivery of the injection distributor can

vary in a rotation field of the crank from 15 degrees before the top

dead center, to five degrees after the top dead center, in the initial phase of

intake. Unscrew the distributor bolt with a corresponding

eye connection, corresponding to cylinder number 1 (see figure 47A), and check

that the beginning of the aperture of the clockwise opening of

the inside rotor coincides with the position of the piston indicated above. The

timing can be done with claw-clutch in the distributor

(see figure 47B) and with the reduction gear on the camshaft (see figure 47C).

To help you in the timing, there are two marks which must correspond both on the

cam shaft of the distributor and on the grooved

part of the motor (see figure 47D).

Page 18

Click here to go to the table of contents